French automotive parts supplier Valeo specializes in designing, manufacturing, and selling components, integrated systems, and modules for passenger cars and trucks, along with providing related services. RT-LAB's Rapid Control Prototyping (RCP) solution accelerated Valeo's development of innovative motor drive systems. In this case, Valeo aimed to develop a new electric power system for electric vehicles.

The R&D department of Valeo in Créteil, France, previously relied on prototype test benches to design new algorithms and control strategies and validate their effectiveness. This approach was costly and time-intensive, as it typically required writing and executing substantial computer code, while demanding programming expertise from development engineers. Due to limited flexibility, engineers struggled to promptly adjust/modify control loops, complicating troubleshooting.

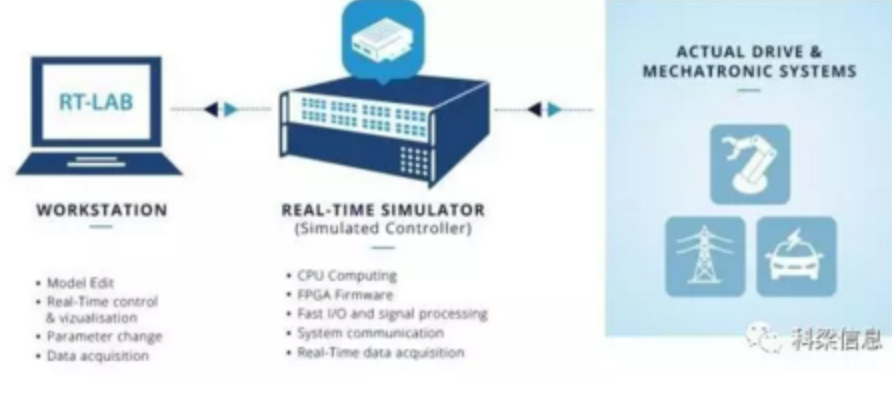

Real-Time Simulation Platform Integrated with Simulink

In preliminary R&D testing, Valeo consistently used Simulink. Given this situation, the RT-LAB Rapid Control Prototype Drive System (RCP-Drive) allows users to automatically load Simulink models onto a real-time simulation platform configured with project-specific I/O interfaces (e.g., PWM, voltage/current sensors, speed sensors).

Utilizing an RCP solution, mathematical models can be automatically imported (from MATLAB/Simulink) into a real-time simulator configured with input/output (I/O) interfaces before being connected to the physical system. In a simulated test environment, the controller's functionality is rapidly validated, ensuring efficient and accelerated project execution.

Fast and Practical HCI and Data Logging

By utilizing the RT-LAB real-time simulation platform, Valeo saved significant work time and costs, creating opportunities for the company’s other industrial projects. The fast and practical Human-Computer Interface (HCI) and data logging solution enables users to quickly pinpoint various details of issues without additional tools.

More Accurate and Flexible

The Pulse Width Modulation (PWM) management system is both rapid and precise, and can be modulated using Simulink software. Its flexibility enables users to conduct in-depth testing. By trialing new control algorithms, Valeo successfully demonstrated novel electric vehicle concepts and addressed modern market challenges

Its advantages lie in:

Innovative technology synchronizes generated PWM signals with Analog-to-Digital Conversion (ADC) data acquisition, preventing the system from sampling signals during switching events and thereby avoiding interference. The powerful “Resolver Input” capability acquires sine and cosine signals from physical resolvers and converts them into positional information on the model.

The RCP function reduces development time by enabling engineers to immediately rectify errors during the early stage of product development. By previewing products in the initial design phase, engineers can correct potential flaws and adjust designs, thereby preventing further losses.

The RT-LAB rapid prototyping solution is precisely tailored to meet the needs of motor control, various motors, and power conversion topologies:

The system can connect to thousands of I/O channels, enabling the simulation of complex systems (PCI Express bus)

FPGA patented technology brings higher simulation power and flexibility in data acquisition

The unique real-time simulation software enables model editing, visualization, and testing procedures

The open architecture of the RT-LAB real-time simulation platform supports seamless integration with third-party components.